Pumps create various features of work and lifetime

greatly easier, and whether you manage a water treatment works or are housework

your car windbreak whilst driving, someone somewhere bank on on the humble

pump. But how precisely do pumps work? Today we’ll explain how the common

centrifugal pump works.

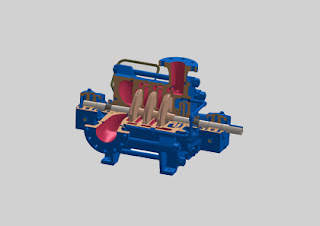

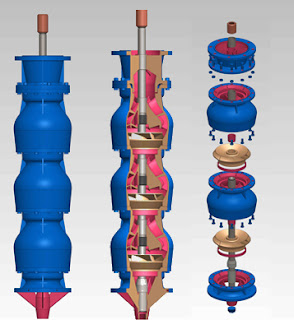

While a centrifugal pump is triggered, an electric motor

origins a tack or fan-like device called an impeller to revolve. Centrifugal

force makes the spinning impeller push water outwards, creating a low-pressure

area at its center. Water flashes in to fill the void and the pressure forces

it out through the discharge pipe via spinning vanes.

For all

centrifugal pumps, head is one of the

important thing and devours close connection with the pressure. Ok formerly you

drive any advance, it is better that you take an idea around the head. Let’s

put it humbly, it means the height at which the pump is proficient of enchanting

the water in an upward direction. It is important that you are conscious of the

discharge head for the following reasons –

·

To mark that the pump is bursting by enough

capacity.

·

In demand to mark an estimate of the filling box

density where the discharge controller has got shut down along with the

functioning of the pump.

·

For outcome whether the pump is working at his

BEP (best efficiency point). As and when the pump purposes out of BEP, the channel

have a habit of to diverge near the circular side loading which give rise to

various problems with bearings, couplings, mechanicals seals and packing.

·

In order to avoid cavitation matters if the head

is considerably low.

·

It should be done in order to choose a right

sized pump for new application.

If you really want to an understanding roughly the head,

make sure that you have grasped the following mentioned points –

·

Make a right deviousness of the force and

discharge heads from losses in the piping. Make sure that you patterned other

associated hardware as well.

·

Discharge pressure gauge or the chart logged

that is installed in the direction of the pump’s discharge end should be

closely checked.

Well, it is informal said than done, there are still mixed

matters that can approach problems while pivotal accurate head. The main reason

behind is the chances in the expulsion system. Following subsections will

discuss how the conniving and process can end up manipulating the emancipation

system.

Designing Issues -

·

There is a continuous change in the speed of the

pumps motor.

·

A mechanical closure has been installed, which

has increased the speed of the motor. Hence, this has led to the variation in

BEP (best efficiency point).

·

The smaller pump’s discharge check valve is

closing by a bigger pump.

·

A pump of wrong size has been installed. This,

most of the times, take place in new applications.

·

Check whether two or more pumps are running

parallel.

Operational Issues -

·

There is a difference in the infection of the

product.

·

There takes a discrepancy in the product’s gluiness.

·

A different product has been introduced via the

piping. When we talk about pipeline applications, this is one of the common

issues that comes across.

·

In order to save amperage, the release regulator

has been shut down.

·

The actual gravity of the creation has suffered

a change, thus it has transport up variation in the rpm of the motor.

The beyond info will definitely help you in plummeting

the errors that may take place owing to the lack of cognizance about the changing

discharge conditions in a water pump & specially for Centrifugal Pumps.